Video

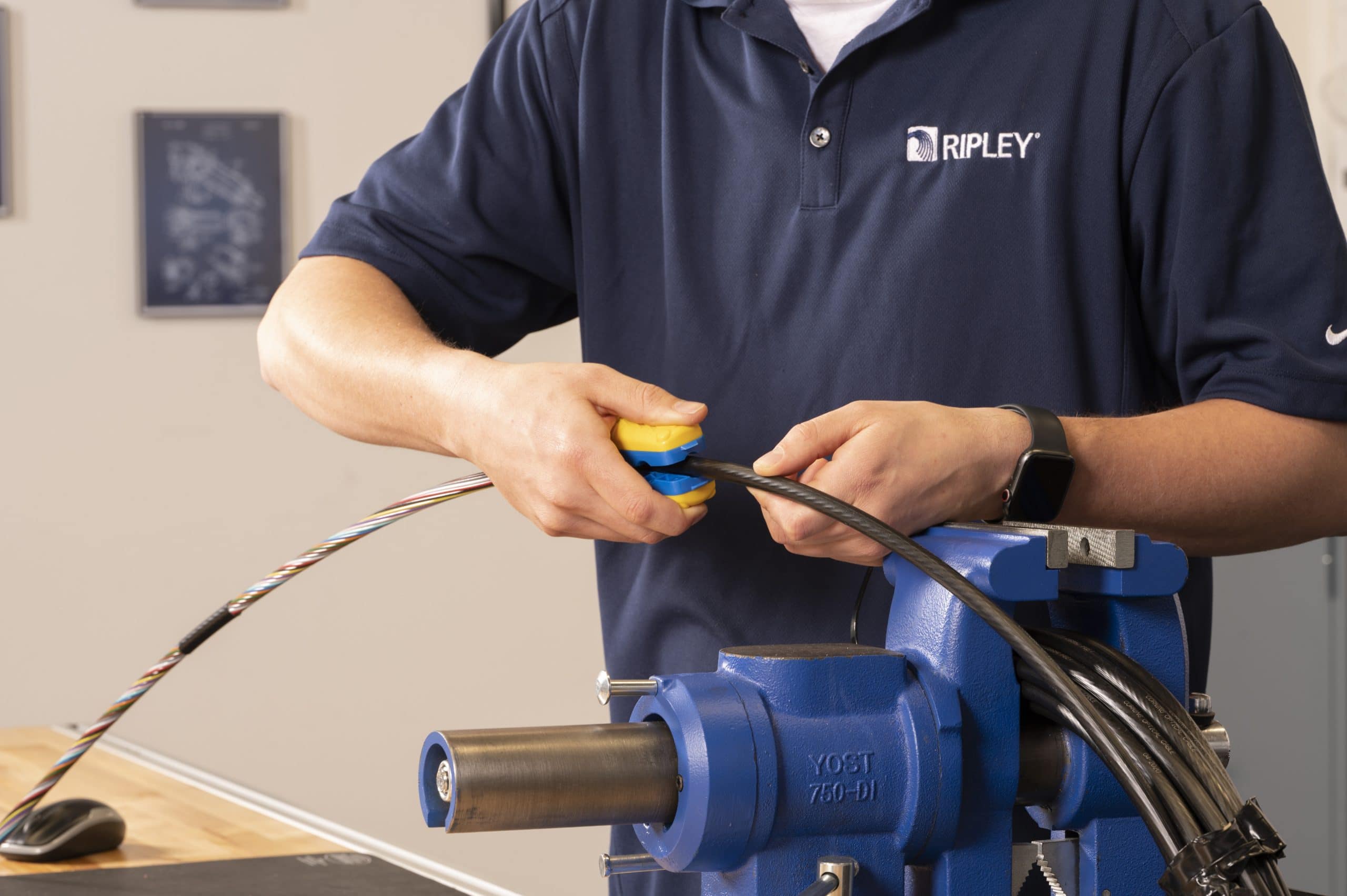

Miller® MC02 Fiber Duct Cutters

If you have an idea to share or a problem to solve we can put 100 years of R&D experience behind you, working with you to create the tools that will change the game.

Email us at ripley_website@hubbell.com

Case Study

4th May, 2022

At Ripley Tools, we know that as cables are constantly evolving, cable prep tools need to evolve rapidly too in order to enable linemen to

Case Study

4th May, 2022

In developing the innovative RocketRibbon™ Extreme Density Cable (1728 fiber count), Corning required a reliable tool to access fiber in mid-span applications with higher repeatability

Case Study

4th May, 2022

Background Openreach is the UK’s digital network provider. It’s in the process of rolling out ultrafast full-fibre broadband across the nation. To do this

At Ripley Labs, we’re always listening, learning and improving. We want you to come to us when you’re missing the perfect tool for any cabling job or when you’re frustrated with missing features on the tools you’re using. We also want to hear from you if you need help developing a prototype you’ve been working on.

Bring us your ideas and we’ll bring them to life. That’s exactly what we did when we met Andy Sedlacek, the inventor of the US16.

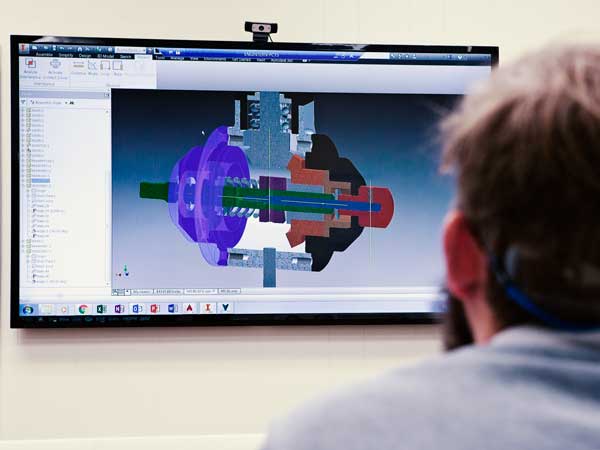

In the hands of our experienced R&D engineers, concepts quickly become prototypes. We then use our expertise to develop industry-first, professional-grade, patented tools – and it all happens here, on site at Ripley Labs.

When you collaborate with Ripley Labs, you get access to:

If you need a tool for a specific application but have no idea what that might look like, we can help. We’re well versed in designing custom tools to fit exacting requirements and will work closely with you to understand needs before developing the ideal solution.

When you collaborate with Ripley Labs, you can expect:

Our engineering capabilities extend beyond the manufacture of mechanical tools, to also cover electrical and digital specialisms. We work with our customers to create embedded and front end software and firmware, for specific applications.

When you collaborate with Ripley Labs, we will support you to:

Ripley Labs is an ISO9001 certified site and can provide access to a full range of quality control (QC) test equipment including coordinate measuring machines, optical comparators, hardness testers and quick scopes. We follow Six Sigma techniques and lean principles to ensure continuous improvement in our systems and operations

We use cutting-edge 3D printing technology to design, manufacture and repair tools and fixtures; providing Mastercam modeling expertise, process design and enhancement and support for all internal assembly and machine technologies.

Our manufacturing capabilities include waterjet cutting, CNC machining, surface finishing and product assembly. It all takes place on site here at Ripley Labs and you can be certain we’ll always deliver to the highest standards.

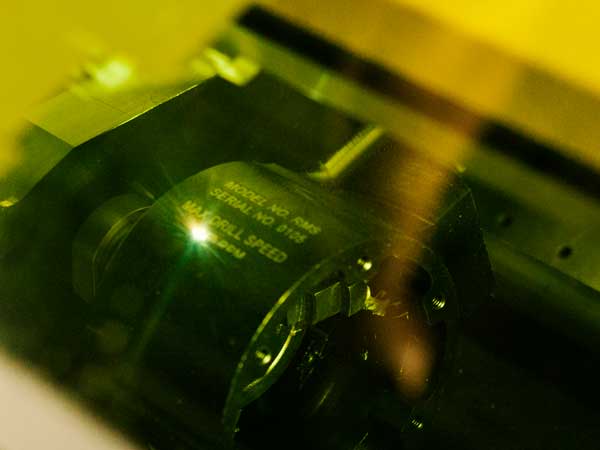

CNC milling

CNC turning

CNC wire-cut EDM